In today’s fast-paced world, efficiency is the name of the game, and polyethylene (PE) foam products are stepping up to the challenge. These lightweight champions are not just about cushioning; they’re about transforming the way we think about packaging, insulation, and beyond. Imagine a world where your materials not only protect but also enhance your operations—sounds dreamy, right? Well, it’s possible with the right strategies!

Let’s take a small break from our article. Do not forget to review Durfoam‘s service pages below:

To truly maximize efficiency with PE foam, start by understanding its unique properties. This foam is not only durable but also resistant to moisture, making it a fantastic choice for various applications. Whether you’re in the packaging industry or working on construction projects, knowing how to leverage these characteristics can lead to significant time and cost savings.

Consider this: when you choose PE foam, you’re opting for a material that can reduce waste and improve product safety. By implementing best practices in handling and application, such as precise cutting and proper layering, you can ensure that every piece of foam works hard for you. So, are you ready to dive into the world of PE foam and unlock its full potential? Let’s get started!

Understanding PE Foam Properties

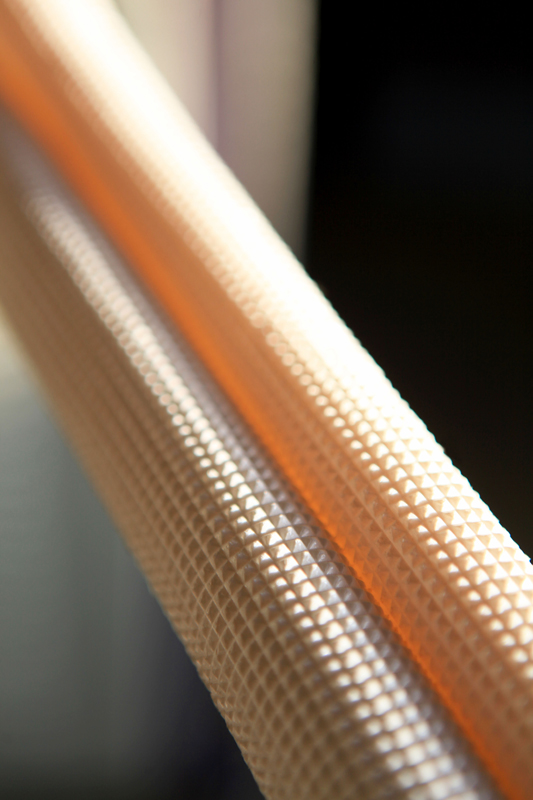

When it comes to materials that blend lightness with strength, polyethylene (PE) foam stands out as a champion. This remarkable material is not just a pretty face; it boasts a range of properties that make it suitable for various applications. First off, its lightweight nature means that it can be easily transported and handled, saving both time and energy in your projects. Imagine trying to lug around heavy materials—now, wouldn’t you prefer something that feels like a feather?

Moreover, PE foam is incredibly durable. It can withstand the test of time and various environmental conditions without losing its structural integrity. This durability is complemented by its moisture resistance, which ensures that it performs well even in humid or wet conditions. So, whether you’re using it for packaging delicate items or providing insulation in construction, you can rest assured that PE foam will hold its ground.

In addition to these properties, PE foam is also non-toxic and recyclable, making it an environmentally friendly choice. These characteristics not only enhance its appeal but also make it a responsible option for modern applications. So, next time you think of PE foam, remember it’s not just another material; it’s a versatile solution that can elevate your projects to new heights!

Applications of PE Foam in Various Industries

Polyethylene (PE) foam is a remarkable material that finds its way into various industries, proving its versatility and efficiency time and again. From packaging to construction, this lightweight yet durable foam is revolutionizing how products are protected and insulated. Imagine receiving a fragile item, perfectly cushioned in a custom-fit PE foam insert—this is just one example of how it enhances the unboxing experience while ensuring safety during transit.

In the automotive sector, PE foam plays a crucial role in minimizing noise and vibration, providing a quieter ride. Its moisture resistance also makes it ideal for use in various components, protecting sensitive parts from water damage. Not to mention, its thermal insulation properties are invaluable in maintaining optimal temperatures within vehicles.

Furthermore, PE foam is extensively used in the construction industry for insulation purposes. It helps in reducing energy costs by providing effective thermal barriers. With its ease of application, contractors can quickly install PE foam boards, ensuring that buildings are not only energy-efficient but also comfortable. The foam’s adaptability allows it to be cut and shaped to fit any space, making it a go-to choice for builders.

In summary, PE foam’s applications are as diverse as the industries it serves, making it an essential material for enhancing efficiency and safety. Whether it’s packaging, automotive, or construction, the benefits of using PE foam are undeniable, showcasing its role as a game-changer in modern manufacturing and design.

Best Practices for Using PE Foam

When it comes to maximizing the potential of PE foam, understanding the best practices for its use is crucial. First and foremost, always measure twice and cut once. This age-old adage rings especially true with PE foam, as its unique properties can make it tricky to work with. Cutting it accurately ensures you minimize waste and maximize efficiency.

Another key point is to handle the foam with care. While PE foam is durable, it can be susceptible to tearing if not treated properly. Always use a sharp blade for cutting, and consider using a straight edge to guide your cuts. This will help maintain clean edges and prevent unnecessary damage.

Storage is also essential. Keep your PE foam in a cool, dry place to prevent moisture absorption, which can compromise its effectiveness. Additionally, avoid stacking heavy items on top of your foam sheets, as this can lead to deformation. If you’re working on a large project, consider using a

| Storage Method | Benefits |

|---|---|

| Vertical Storage | Prevents deformation |

| Flat Storage | Maintains shape |

to keep your materials organized and in optimal condition.

Lastly, always test a small piece of foam in your application before going all in. This will help you understand how it behaves under different conditions, ensuring you achieve the best results. By following these best practices, you can ensure that your PE foam products not only perform well but also last longer, ultimately saving you time and money.