Before starting our article, do not forget to review the following pages of Durfoam:

Chemically cross-linked polyethylene foam is revolutionizing the way we think about sustainability in various industries. This innovative material offers a plethora of benefits that go beyond traditional foam products. By combining exceptional properties with eco-friendly characteristics, it has become a go-to choice for creating sustainable solutions that meet the demands of a rapidly changing world.

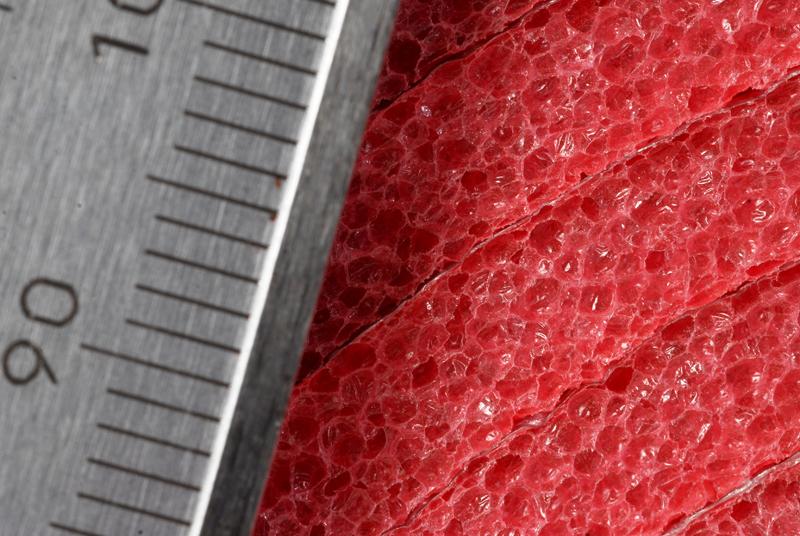

Imagine a material that not only provides excellent cushioning and insulation but also actively contributes to reducing environmental impact. Chemically cross-linked polyethylene foam does just that. Its closed-cell structure not only ensures superior shock absorption but also makes it highly resistant to water, chemicals, and temperature fluctuations. This makes it an ideal candidate for applications where durability and sustainability are paramount.

When it comes to packaging and insulation, chemically cross-linked polyethylene foam shines as a standout performer. Its lightweight nature combined with exceptional thermal insulation properties makes it perfect for eco-friendly packaging solutions. Additionally, its ability to resist moisture and mold growth makes it an excellent choice for energy-efficient insulation in buildings and appliances.

Moreover, the advancements in recycling technologies for chemically cross-linked polyethylene foam are paving the way for a more sustainable future. By implementing efficient recycling processes, we can reduce waste, conserve resources, and minimize the environmental footprint of foam products. This shift towards a circular economy not only benefits the planet but also opens up new possibilities for creating innovative and eco-conscious products.

Properties of Chemically Cross-Linked Polyethylene Foam

Chemically cross-linked polyethylene foam boasts a remarkable set of properties that set it apart as a versatile and sustainable material. One of its key attributes is its exceptional durability, making it resistant to wear and tear even in demanding applications. Additionally, this foam material exhibits excellent thermal insulation properties, providing effective temperature regulation and energy efficiency.

Furthermore, chemically cross-linked polyethylene foam is known for its lightweight nature, making it easy to handle and transport while still offering robust protection. Its closed-cell structure not only enhances its buoyancy but also prevents the absorption of water, making it ideal for use in moisture-sensitive environments. This foam material also demonstrates superb chemical resistance, ensuring long-term performance in various conditions.

Moreover, the flexibility and cushioning properties of chemically cross-linked polyethylene foam make it a preferred choice for impact absorption and shock resistance. Whether used in packaging to safeguard delicate items during transit or in sports equipment to enhance safety, this foam material excels in providing reliable protection. Additionally, its sound-dampening capabilities contribute to creating quieter and more comfortable environments.

Applications in Packaging and Insulation

When it comes to the applications of chemically cross-linked polyethylene foam in packaging and insulation, the possibilities are vast and environmentally friendly. Picture this – a world where your packages are not only securely protected but also wrapped in a material that has minimal impact on the planet. That’s the magic of chemically cross-linked polyethylene foam.

Let’s delve into the packaging realm first. Imagine receiving a fragile item in the mail, encased in a cushiony material that not only keeps it safe from the bumps and jostles of the journey but is also completely recyclable. Chemically cross-linked polyethylene foam offers excellent shock absorption properties, making it ideal for protecting delicate items during shipping. Its lightweight nature adds another layer of convenience, reducing overall packaging weight and the associated carbon footprint.

Now, shifting gears to insulation applications, this versatile foam plays a crucial role in enhancing energy efficiency. Whether it’s insulating your home, office, or a refrigeration unit, chemically cross-linked polyethylene foam provides superior thermal insulation. By effectively trapping heat or cold air, it helps maintain desired temperatures while reducing energy consumption. This not only translates to cost savings but also contributes to a greener environment by lowering overall energy usage.

Moreover, the durability and moisture resistance of chemically cross-linked polyethylene foam make it a reliable choice for long-term insulation needs. It can withstand varying weather conditions and moisture levels without compromising its insulating properties, ensuring consistent performance over time. This resilience adds to its appeal as a sustainable solution for insulation applications across different industries.

Advancements in Recycling and Waste Management

Advancements in recycling and waste management play a crucial role in the sustainability of chemically cross-linked polyethylene foam. With the increasing focus on environmental conservation, innovative technologies have emerged to address the challenges of recycling this versatile material. One of the key advancements is the development of specialized recycling processes that can efficiently break down and reprocess chemically cross-linked polyethylene foam, allowing for the creation of new products without compromising quality.

Through these advancements, the industry is moving towards a more circular economy where materials are reused and recycled, reducing the overall environmental impact. Companies are investing in research and development to improve the efficiency of recycling methods, ensuring that chemically cross-linked polyethylene foam can be repurposed effectively. This not only minimizes waste but also conserves resources, making a significant contribution to sustainable practices.

Moreover, collaborations between manufacturers, recyclers, and policymakers are fostering a holistic approach to waste management. By implementing comprehensive recycling programs and promoting awareness among consumers, the industry is striving to create a closed-loop system for chemically cross-linked polyethylene foam. This collective effort is essential in achieving long-term environmental goals and reducing the reliance on virgin materials.

Furthermore, the advancements in recycling technologies are enhancing the quality and purity of recycled chemically cross-linked polyethylene foam, making it suitable for a wide range of applications. From new packaging materials to innovative insulation solutions, recycled foam is finding its way into various products, demonstrating the economic and environmental value of sustainable practices.